Measurement & Verification Professionals

What is M&V?

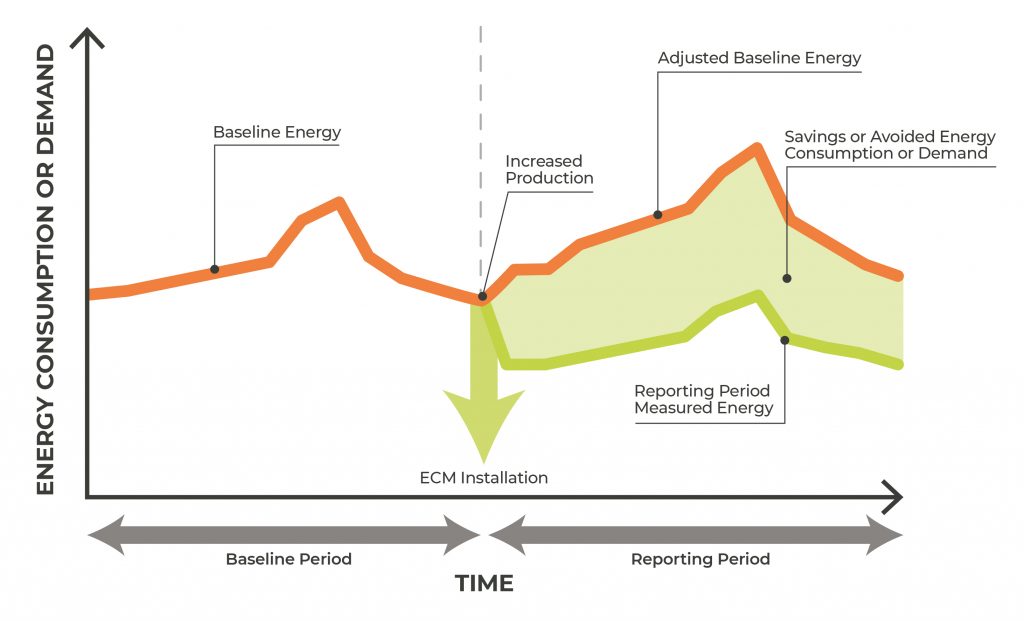

Measurement and verification (M&V) is the process of planning, measuring, collecting, and analysing energy consumption data. Measurement of energy savings involves measuring a site’s energy usage before and after the implementation of an Energy Efficiency Measure (EEM) and data analysis (including developing mathematical models).

Verification is the process of verifying the EEM is operating as expected and continues to operate as intended. Certificates for abatement can be awarded for energy savings achieved as a result of the EEM.

How M&V Works

Energy savings through the use of Measurement & Verification (M&V)

involves measuring energy consumption, collecting site data, and modelling site energy use before

and after implementing an Energy Efficiency Measure (EEM).

The Baseline Energy is established before the implementation of the EEM and determines

how and why the site uses energy through statistical modelling. This forms the

Baseline Energy Model.

Once the implementation of an EEM is complete, the Operating Energy

(or Reporting Period Energy) is measured and compared to the baseline to determine the verified

Energy Savings.

×

![]()

M&V Project Types.

Our M&V service covers all types of EEM projects, including:

Energy Efficiency Upgrades

- Heating, Ventilation & Air Conditioning (HVAC)

- Refrigeration

- LED Lighting

- Air Compressors

- Steam Boilers

- Water Boilers & Heaters

- Variable Speed Drives (VSDs)

Process Optimisation

- Building Management Systems (BMS)

- Heat Recovery

- Production/Process Improvements

Onsite Renewable Energy

- Solar PV

- Bio Energy